Fluids are essential in many industrial processes. Industrial processes should be accurate and precise, hence measuring fluids involved in any industrial process, liquids, or gases is critical. Ultrasonic flow meters are accurate and straightforward for measuring as well as recording fluid flow rates. Accuracy in measuring fluid flow rates leads to better quality control, increased service delivery, and better management of resources, leading to increased revenue.

Ultrasonic Flow Meter

Contents

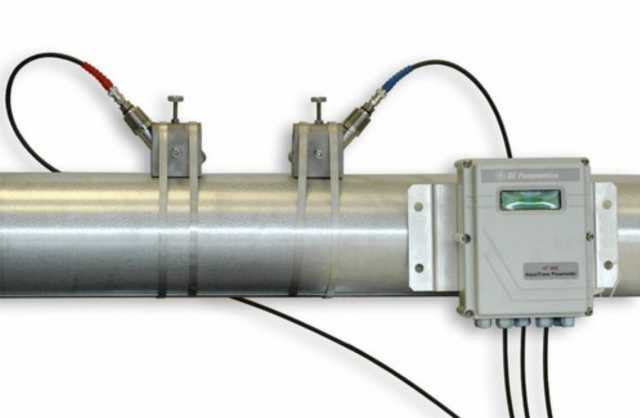

An ultrasonic flow meter employs ultrasound technology and measures the velocity of liquids and gases using sound emitted by transducers, with frequencies higher than the human audible range to calculate the volume flow of fluids through a pipe.

Working of Ultrasonic Meter Works

Ultrasonic flow meters send and receive ultrasonic sound waves from both upstream and downstream transducers.

When there is no flow, the ultrasound takes an equal amount of time traveling downwards to the downstream transducer and upwards to the upstream transducer. The downstream and upstream sound frequencies also remain the same when there is no fluid flow.

The upstream transducer sends ultrasonic sound waves to the downstream transducer along with the flow of the fluid. On the other hand, the downstream transducer receives the sound waves and emits ultrasonic sound waves upwards to the upstream transducer against the fluid flow.

The difference in time between the downward travel and the upward transmission of the sound waves is directly proportional to the flow rate. The higher the fluid velocity in the pipe, the higher the time difference between the downward movement and the upward transmission of the ultrasonic sound.

The ultrasonic flow meter then converts the time difference to velocity and volume and records the data.

The Importance of Ultrasonic Flow Meter

The integration of ultrasonic technology in fluid flowmeters has increased confidence in the reliance on flowmeters for integrity and accurate data.

1. Easy to Instal

A clamp-on ultrasonic flow meter is easy to install since it is non-invasive. You can install a clamp-on ultrasonic flowmeter without shutting down the system since it is non-invasive.

2. Low Maintenance Cost

Unlike magnetic flow meters, which require the replacement of electrodes, ultrasonic flow meters do not have moving parts; hence there is no risk of wear and tear.

3. Suitable For Slow Flow Rates

Ultrasonic flow meters are highly accurate; they can detect even the slowest flow rate with minimal errors.

4. High Accountability

The ultrasonic flow meter technology is highly accurate hence suitable for accounting for each drop of valuable products such as petroleum products and food products. By measuring the correct quantities of products, it enhances integrity in industrial processes.

5. Resistant to Extreme Conditions

The ultrasonic flow meters can handle extreme industrial conditions. They are resistant to high temperatures and can withstand high pressures without malfunctioning.

6. Enhances Safety

Temperature and pressure are critical safety concerns when operating with enclosed fluids. Hence, accurately measuring the flow rate of fluids in pipes can detect an anomaly with the fluid flow.

Applications Of Ultrasonic Flow Meter Technology

- Oil and gas industry

- Food and beverage industry

- Metals and mining industry

- Pharmaceutical industry

- Water and sewage industry

- Chemical industries

Conclusion

Ultrasonic flow meters provide a simple, non-intrusive way of measuring the flow of fluids through pipes hence avoiding the need to cut through the fluid lines during installation. The accuracy of the ultrasonic flowmeters ensures a high level of accountability for highly valued fluids, thus enhancing integrity. With the ability to accurately measure the flow of fluids in both directions and the low maintenance costs, ultrasonic flowmeters are becoming the technology of choice in measuring the flow of fluids.