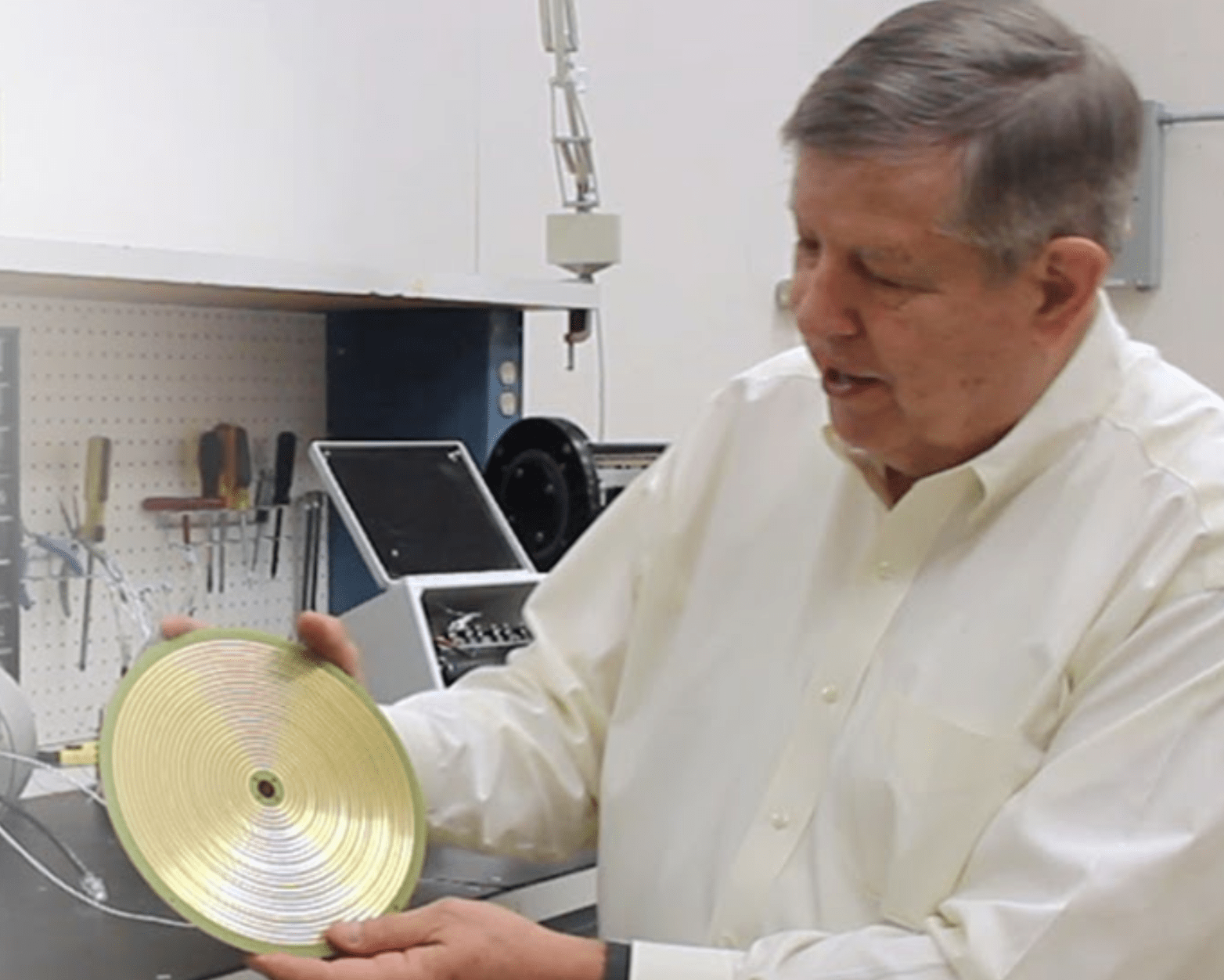

A pancake slip ring is probably one of the most popular slip rings that you will ever come across. These types of slip rings are mostly used in wind turbines, alternators, as well as other mechanical and electric motors with vertical length limitations. As you can tell from its name, the pancake slip ring features a platter like the design. Hence, it offers a low vertical height that’s compensated for through the horizontal length.

The pancake slip rings come in a wide range of models and specifications. But mostly, they are unique to the specific designs and applications. That said, before choosing a slip ring to suit your needs, you must review the available options. Want to know more about pancake slip ring, you can visit this page With that in mind, let’s take a look at the applications of pancake slip rings in the electromechanical industry.

How Do the Pancake Slip Rings Work?

Contents

Before we proceed, let’s first take a look at the pancake slip rings that have so much in common with the high voltage slip rings. They mostly come with two main parts; one the stationary brush made of graphite and the other features a rotating ring.

When it comes to the rotating component of the slip ring, the material and diameter may vary mostly depending on the unique requirements for the application of the slip ring. All in all, generally, the slip rings just use the same underlying mechanisms where the stationary metal graphite brushes the convert electrical signals on to the rotating component.

What Sets Apart the Pancake Slip Rings

Slip rings transfer electric signals and data from the stationary components to the rotating parts. All in all, some merits in the pancake slip rings help to distinguish them from others in the same category. We have a wide range of slip rings, including the USB slip rings, fiber optics, PCB, and miniature, among others. Each of these slip rings models suits specific applications, and that is why you are always advised to state the particular requirements of the application before ordering a slip ring. That said, let’s take a look at the things that set apart the pancake slip rings from the others.

- Pancake slip rings are designed to suit applications where there is limited verticals space

- Pancake slip rings offer low friction while at the same time minimizing electronic noise and torque

- They come with a unique metallic brush and a high vacuum technology that helps to improve the rotating performance

- They can also function as hydraulic slip rings if used in fluid media applications

All in all, a coin always has two sides. And when it comes to the pancake slip rings, they have a few shortcomings. To start with, they are not the best fit where there is a need for high-speed rotations. What’s more, they don’t have a design as robust as other slip rings like the high voltage slip rings.

The Different Applications of Pancake Slip Rings

Especially when paired with silver, pancake slip rings offer the most effective results. However, there are still several other factors that you need to pay attention to before you get these electromechanical devices.

When it comes to choosing the ideal pancake slip ring for your needs, it all comes down to identifying the brands and reputable vendors that will provide pancake slip rings that can match up the needs of your machinery as well as the general use. With that in mind, the typical applications of pancake slip ring in the electromechanical industry include:

Offshore Cranes

The offshore cranes feature an exciting combination of high voltage slip rings. However, they still include the pancake slip rings design in their mechanisms. The pancake slip rings in this case, help in running any components in the offshore cranes that may be having limited vertical space. Mostly, the elements that require full rotation motions.

Automobile Showrooms

Another primary application of the pancake slip ring is in the automobile showrooms. The fact that the slip rings come in a flat design, they are the most ideal for low to medium speed rotations, which are what is needed in the automobile showrooms. What’s more, these pancake slip rings accommodate the heavy mass rotation of showroom vehicles usually displayed in circular motions and paths.

Microwave Ovens

Probably the most common use of pancake slip rings, the microwave uses the pancake slip rings to rotate the disk where you place your food at. And the fact that they are also available in a range of tracks and speeds, you can also find them in some other electric motors that have some rotating components.

In Summary

As we have seen from this article, pancake slip rings can be used in a wide range of electromechanical systems that have rotating parts. With its impressive slim design, they are suitable for most applications that have more vertical room as compared to the vertical space. All in all, before ordering your slip ring, you need to review the specifications of your application. That will ensure you get a pancake slip ring that suits your use.