After more than 15 years of experience as a plastic surgeon, the 2020 Australasia award winning doctor, Dr Dryqiel, realized that by taking advantage of today’s major innovations in 3D printing, he can now bring a major revolution in the world of aesthetic medicine. Using latest technologies, Dr Dryqiel’s startup, Face2be, introduces a game-changing solution by offering high-end 3D-printed custom facial implants at low-cost.

While out-of-the-box implants have become quite affordable, custom ones used to be very expensive.

Ready-Made implants: an ineffective solution…

Contents [show]

Standard ready-made implants come in a universal size. During facial reshaping surgeries they are widely used by surgeons (not to say all the time!). But surgeons know very well the motto « One size doesn’t fit all ». That’s why they usually try to shave the implant intraoperatively. The goal of this process is to best fit the patient’s bone structure in order to obtain natural looking results along with the desired look.

Even with shaving of the implant, it leads, most of the time, to a low satisfaction rate. The reason behind that is simple: our bones contain various curves and crevices. Trying to replicate the bone’s design by simply shaving the implant is not an easy task and not enough.

The rise of custom facial implants

A sudden rise of custom facial implants started few years ago in the world of aesthetic medicine, with the major downside being the cost of production. These custom implants solve all cosmetic issues of a standard ready-made ones, providing natural outcomes and fitting every variables of the bones structure. Numerous world-renowned plastic surgeons offer this attractive solution and market it as the ‘gold standard’ of facial enhancement. It requires for them to get additional competences about 3D computer designing to offer it. That’s the major reason why this technique is offered by only a few ones.

During the designing process, the implant is manipulated in all three dimensions to add volume, size and shape where it is needed. Unlike standard implants, it fits the bone structure like a puzzle piece. The major downside is the cost of the entire process. While those considering out-of-box implants might pay up to $4,000 or $5,000, custom designed implants cost at least 2X or 3X that amount.

The impact of Face2be

That’s where Face2be comes into action. This start-up does the hard work of designing & creating the implants at knock-down prices (as an example, they quoted us $1,600 for a wraparound jawline implant).

Face2be implants are created from the person’s 3D CT scan. But what the design of the implants should be for any person’s cosmetic needs is an artistic guess. The computer can unquestionably not predict the outcomes. It only makes what it is told to do. For this reason, Face2be is not only a team of doctors but also top 3D designers to give that « artistic touch » to the implants.

As a customer, the process is quite easy and user friendly. First they study your face with simple pictures that you send to them and try to understand what are your goals & needs. Once done, they ask for a 3D CT scan that you can get done to any radiology center near your location. Usually the centers give a CD containing your files but, in our case, one has to rather request the files to be sent directly on Face2be dropbox/email. A previsualization model is made from your pictures and CT scan files, allowing you to see what your face could look like post-operation. If approved, they start designing and 3D-printing your implants, and sent directly to your surgeon for operation.

Face2be’s 3D-printing technology

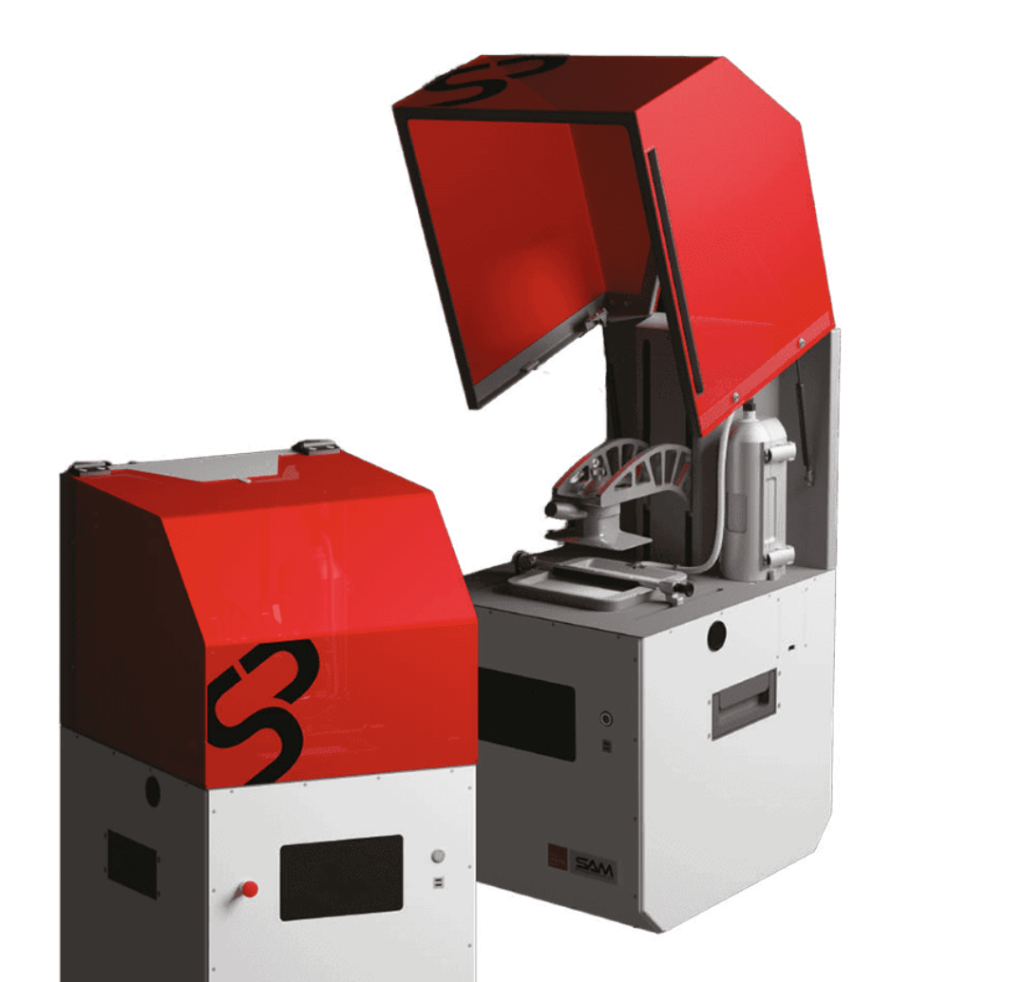

The 3D-printing is done using the latest world’s first medical grade silicone 3D-printer. Silicone Additive Manufacturing (SAM) is the perfect technology in the medical world to unlock new perspectives. It allows processing of 100% medical-grade silicones at high speed & high precision. SAM accomplishes that without the use of any mould. It has a cutting-edge potential to make custom implants (and medical products in general) accessible to anyone.

By using this groundbreaking technology, Face2be can significantly reduce the cost of its custom implants. Face2be’s silicones are ISO DIN EN 10993-05 and ISO DIN EN 10993-10 certified. The gold standard of facial augmentation has never been more accessible. Face2be’s goal is to create a whole new era in the aesthetic medicine.