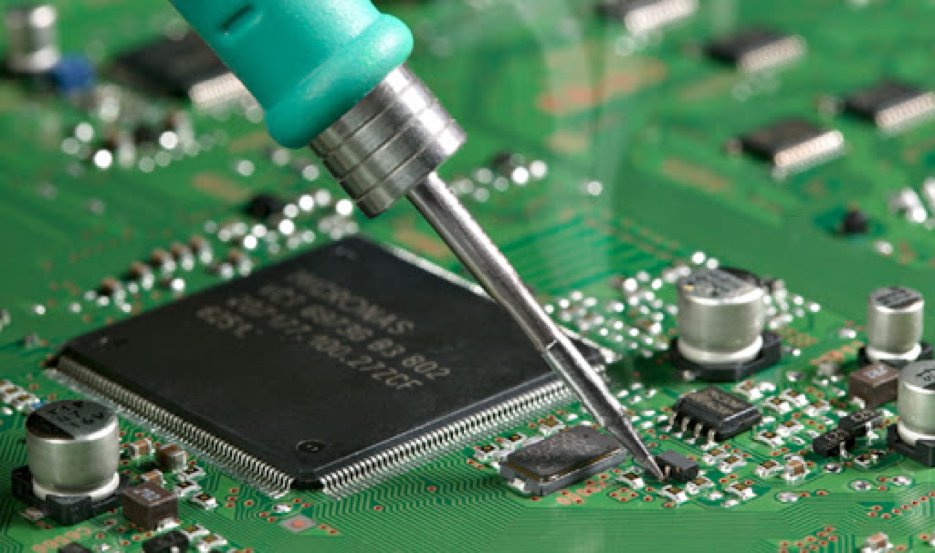

With the continuous development of high-tech, consumers are increasingly pursuing sophisticated products. While many of these sophisticated products cannot be finished by hands. For instance, in the soldering industry, many enterprises have used a robotic soldering system instead of a hand soldering system because of its high efficiency and high precision soldering.

Soldering is one of the most critical procedures in manufacturing electronic equipment. It is the process where two or more items are adhered together by melting a filler metal and letting it cool between the link or joint. The filler metal usually has a much lower melting point than the workpiece.

Robotics Soldering Systems

Contents

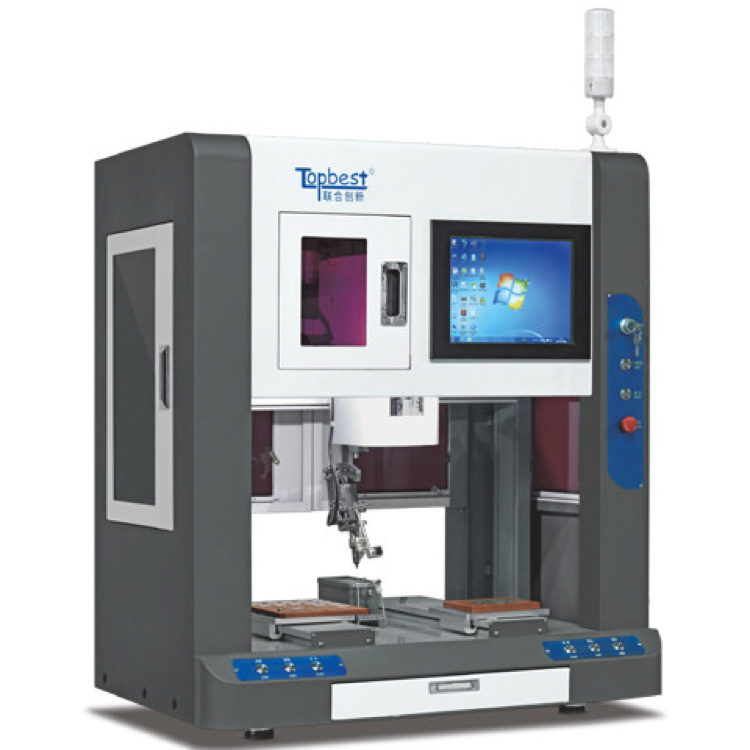

Robotics soldering systems are integrated with more than one machine. Often they come with a default attached desoldering system. This helps operators save a lot of money and eliminate downtime.

The latest technologies have allowed robotics to further integrate other features like rework stations, a vacuum, and a hot air pick up. These robotics soldering machines are best suited for large scale production and high accuracy work. Moreover, many of the latest robotics soldering stations come with programmable software that adapts interfaces for different applications.

Given the advantages of robotic soldering systems over hand soldering, the robotic soldering system is favored by many enterprises. Next, I will analyze the top 3 reasons to choose robotic soldering systems over hand soldering.

Top Reasons to Choose Robotics Soldering Systems Over Hand Soldering

. Smart Heat Management Technology

Temperature management is one of the most crucial factors of a robotics soldering system. If the temperature increases above a specific value, it can lead to faulty soldering and, in turn, significant production errors. Soldering robots come with intelligent heat management technology, allowing the stations to decrease the temperature by a solid 50ºC.

These soldering robots come with advanced software that governs complex algorithms to control heating systems. This, in turn, helps increase the performance of the solder. Today, many advanced robotic soldering machines come with sleep and hibernation features that automatically shut off when the iron tip temperature is very hot.

. Advanced Tip Technology

Robotics soldering units come with ultra-precise heating and temperature control units to manage micro-soldering applications. However, the feed speed also plays a significant role. To tackle this drawback, the robotics soldering machine comes with high control on the soldering feed.

Its technologically integrated tip cartridges deliver and recover at uncanny speeds. Thanks to this technology, even the smallest soldering applications can be easily mastered with precision and safety. The tip is twice as powerful and efficient. These are compact and powerful and guarantee a dynamic performance no matter what.

. Multiple Function Station

The latest soldering units are integrated with other devices to make soldering as precise and safe as possible. Many soldering devices come with desoldering stations and other optical and programmable features. One can easily solder, inspect, and desolder as they like. These stations offer high performance for electronic product research, production, and rework.

Conclusion

Robotics soldering stations are paving the path for a more efficient and productive workplace. The primary purpose of a soldering robot is to replace hand soldering, so you must consider purchasing a top-level robotic soldering system. You should always find such products from well-known companies to gain more experience in the soldering process.

One example in this case is Topbest. Topbest is a national high-tech enterprise with an R & D team of 20 engineers, providing professional solutions for welding, distribution, screw fastening, etc. in the 3C industry.

The Topbest soldering robot has some advanced functions, such as a unique motion controller and teaching pendant. It should be able to operate at extreme speed and accuracy on 2.5 to 3 axes. Anyway, you can select different types of soldering robots according to your company’s business needs.